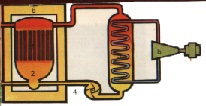

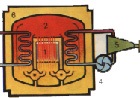

The world's first nuclear power plant used gas-cooled reactors. Built in Calder Hall, Cumberland, England, it went into operation in October 1956. Its four reactors were the precursors of a series of others, also gas-cooled, built in England and other countries to produce electricity. Calder Hall's electrical output is 180MW. However, this type of reactor underwent notable improvements in each of the new plants that were built. The plant currently under construction at Wylfa Point, Anglesey, will produce 1180MW, with its twin reactors. All of these reactors use natural uranium as fuel. Uranium is present in the form of bars, packaged in boxes made from a magnesium alloy. This alloy is called magnox, from which the name given to this type of reactors derives. The magnox casing is made in the form of scales in order to facilitate heat transfer to the refrigerant gas. Moderador is made of graphite, and has the shape of a square grid of bricks, crossed by vertical channels. Fuel rods are stacked in these channels, one on top of the other; some of the channels are occupied by control bars made of steel and boron. The cooling element - carbon dioxide gas - flows through the channels and over the combustible material. The core of a gas-cooled reactor is surrounded by a graphite reflector that bounces back part of the neutrons that escape the reactor. The cooling element, which absorbs heat from the reactor (at a temperature between 350° and 400°C) is used to produce water vapor for the turbo generator. The gas that leaves the heat exchanger is sent back to the reactor using very powerful fans. A cement shield, built around the reactor, protects operators and the public. The heat exchanger is not protected with a biological shield, because carbon dioxide does not become radioactive even though it passes through the reactor core. For the most part, these gas-cooled reactors have very complex equipment, placed at the top, which automatically refuels them during operation.

The world's first nuclear power plant used gas-cooled reactors. Built in Calder Hall, Cumberland, England, it went into operation in October 1956. Its four reactors were the precursors of a series of others, also gas-cooled, built in England and other countries to produce electricity. Calder Hall's electrical output is 180MW. However, this type of reactor underwent notable improvements in each of the new plants that were built. The plant currently under construction at Wylfa Point, Anglesey, will produce 1180MW, with its twin reactors. All of these reactors use natural uranium as fuel. Uranium is present in the form of bars, packaged in boxes made from a magnesium alloy. This alloy is called magnox, from which the name given to this type of reactors derives. The magnox casing is made in the form of scales in order to facilitate heat transfer to the refrigerant gas. Moderador is made of graphite, and has the shape of a square grid of bricks, crossed by vertical channels. Fuel rods are stacked in these channels, one on top of the other; some of the channels are occupied by control bars made of steel and boron. The cooling element - carbon dioxide gas - flows through the channels and over the combustible material. The core of a gas-cooled reactor is surrounded by a graphite reflector that bounces back part of the neutrons that escape the reactor. The cooling element, which absorbs heat from the reactor (at a temperature between 350° and 400°C) is used to produce water vapor for the turbo generator. The gas that leaves the heat exchanger is sent back to the reactor using very powerful fans. A cement shield, built around the reactor, protects operators and the public. The heat exchanger is not protected with a biological shield, because carbon dioxide does not become radioactive even though it passes through the reactor core. For the most part, these gas-cooled reactors have very complex equipment, placed at the top, which automatically refuels them during operation.